Gravity casting is carried out on robotic cell with continuous monitoring of casting parameters.

Aluminium alloys are melted in gas melting furnaces. The metal melting process is computer-assisted.

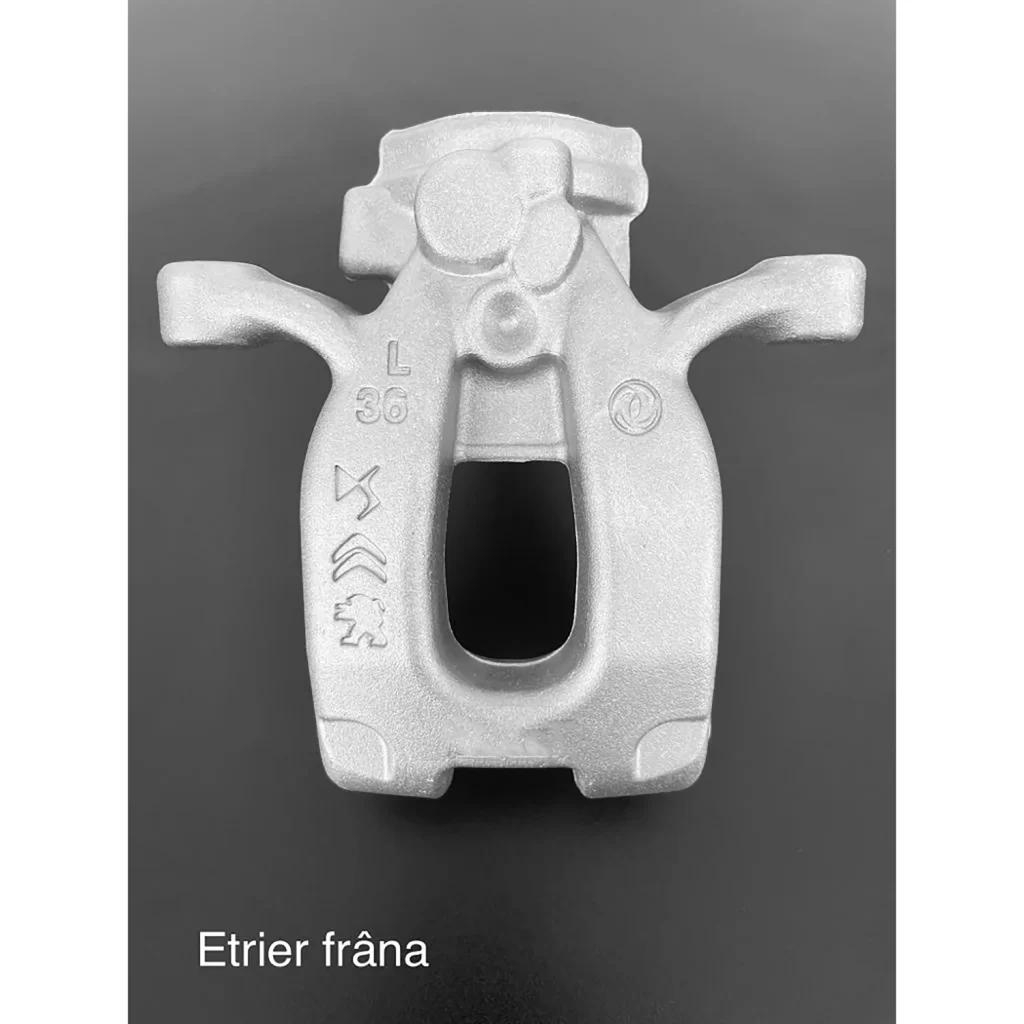

ALTUR is capable of pouring parts in complex configurations with a maximum part size of 400 x 400 mm, weight ranging from 0.1 to 6 kg and minimum wall thickness of 3 mm.

In 2022, the share of gravity casting products was 85% of ALTUR’s total production, and for 2025, the objective is to balance production by increasing the share of die casting.